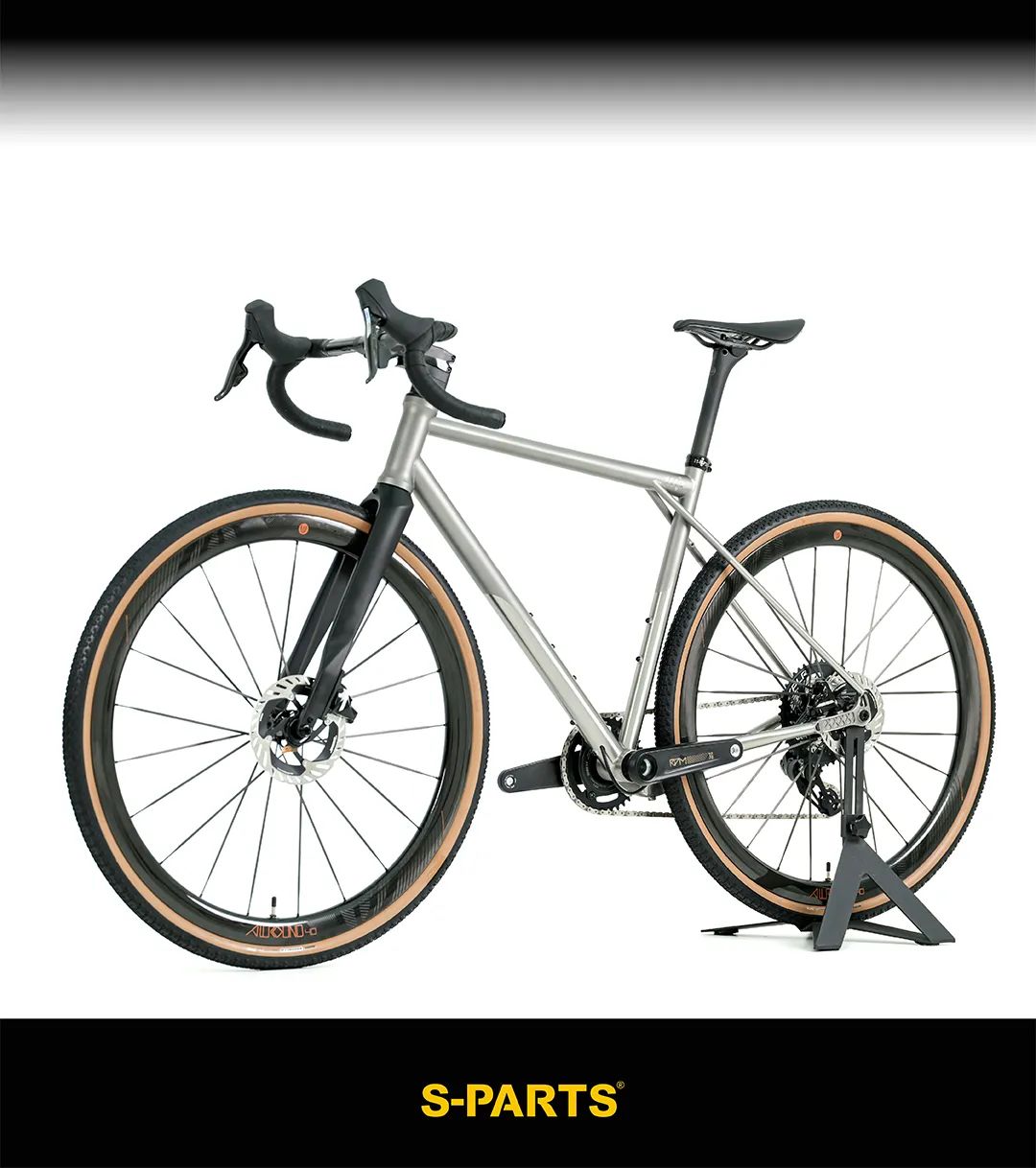

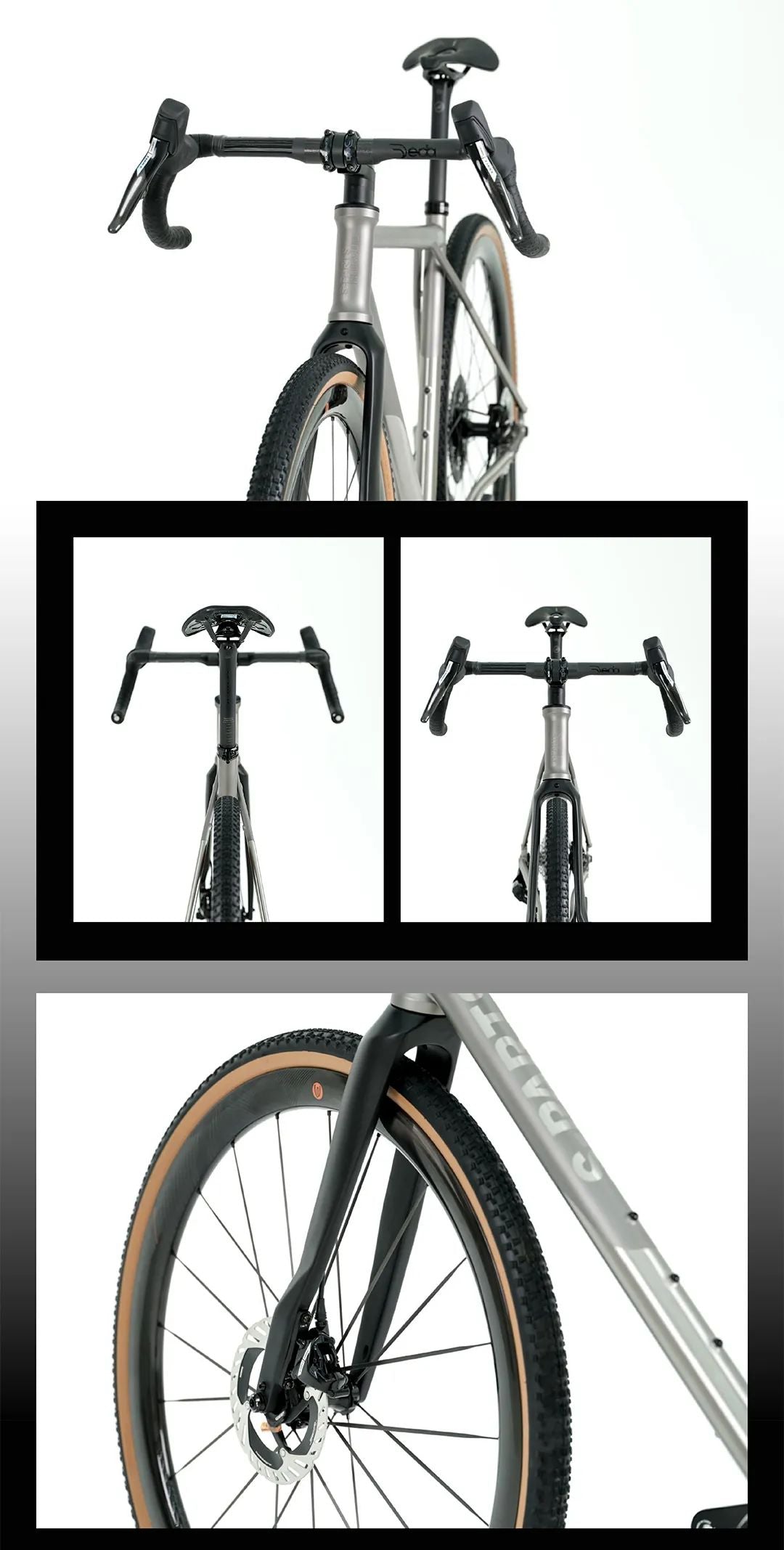

S-PARTS Titanium Alloy Gravel Bike Frame

WHY GRAVLE?

At the inception of designing the first mass-produced titanium alloy bike frame for S-PARTS, we contemplated two questions:

- What type of bicycle is best suited for titanium alloy construction?

- What kind of riding experience and lifestyle should an exceptional titanium alloy bicycle provide?

[Choose, Think, Create]

Titanium's inherent mechanical properties provide a perfect balance between torsional rigidity and vertical damping. It ensures the lateral stiffness needed for high power output during pedaling while absorbing vertical bumps from various complex terrains and filtering high-frequency vibrations. This makes it not only suitable for paved roads but also destined to break free from urban constraints and race through the wild. Whether it's short sprints or long journeys, these are its specialties. This reliable titanium alloy companion is always ready to join you on an adventure, embracing the mountains and rivers that await.

That's why "Gravel" is the most beautiful interpretation of a titanium bike.

CROSS CONTROL SYSTEM 2.0

This is the crowning design that we have meticulously developed and finally achieved for mass production. Years ago, when S-PARTS began its custom titanium frame business, we insisted on using a design where the seat stays connect to the top tube, which we termed "CROSS CONTROL" technology. This method effectively uses the passive deformation of metal to absorb road bumps in non-suspension frames. However, due to early technological limitations, we had to conservatively weld the connection between the seat stays and the seat tube. While this ensured the frame's strength, it significantly compromised the original goal of vertical shock absorption, which was undoubtedly frustrating.

For years, this issue has been on our minds, and the S-PARTS team never gave up on finding the optimal solution. In 2023, we introduced new hydraulic bending equipment and internationally advanced calibration and testing instruments. With these resources, we ventured into more daring tube and profile designs, using 3D software to simulate a completely disconnected structure between the seat stays and the seat tube, which we successfully achieved in simulations. This led to the creation of the "CROSS CONTROL 2.0" system we have today.

We chose slimmer seat stays, internally hydroformed to maintain support strength while providing ample clearance. This design allows for controlled physical deformation on rough roads, achieving the intended shock absorption function. To increase the contact area and vertical support strength at the weld points between the stays and the top tube, we used a special vertical pressing mold at both ends of the top tube. This created two elliptical cross-sections—one horizontal at the head tube and one vertical at the seat tube—achieving both aesthetic and functional benefits.

ASYMMETRIC REAR FORK

Traditional metal frames, when requiring compatibility with both large chainrings and wide tires, usually compress the drive-side chainstay to form a dent. This is an unavoidable compromise that inevitably damages the original tube wall structure, resulting in a loss of strength.

S-PARTS designed a connector CNC-carved from a single piece of titanium alloy plate, perfectly solving this issue in multiple ways:

- The solid titanium alloy connector provides higher connection strength than tube materials, ensuring drive-side pedaling rigidity.

- The 6mm wide plate offers considerable installation space for both tires and chainrings, allowing the GRAVEL frame to accommodate tires up to 42c and chainrings up to 48t.

- The asymmetric recessed design also provides more chain movement space, significantly reducing the chance of chain-to-chainstay collisions during extreme bumps.

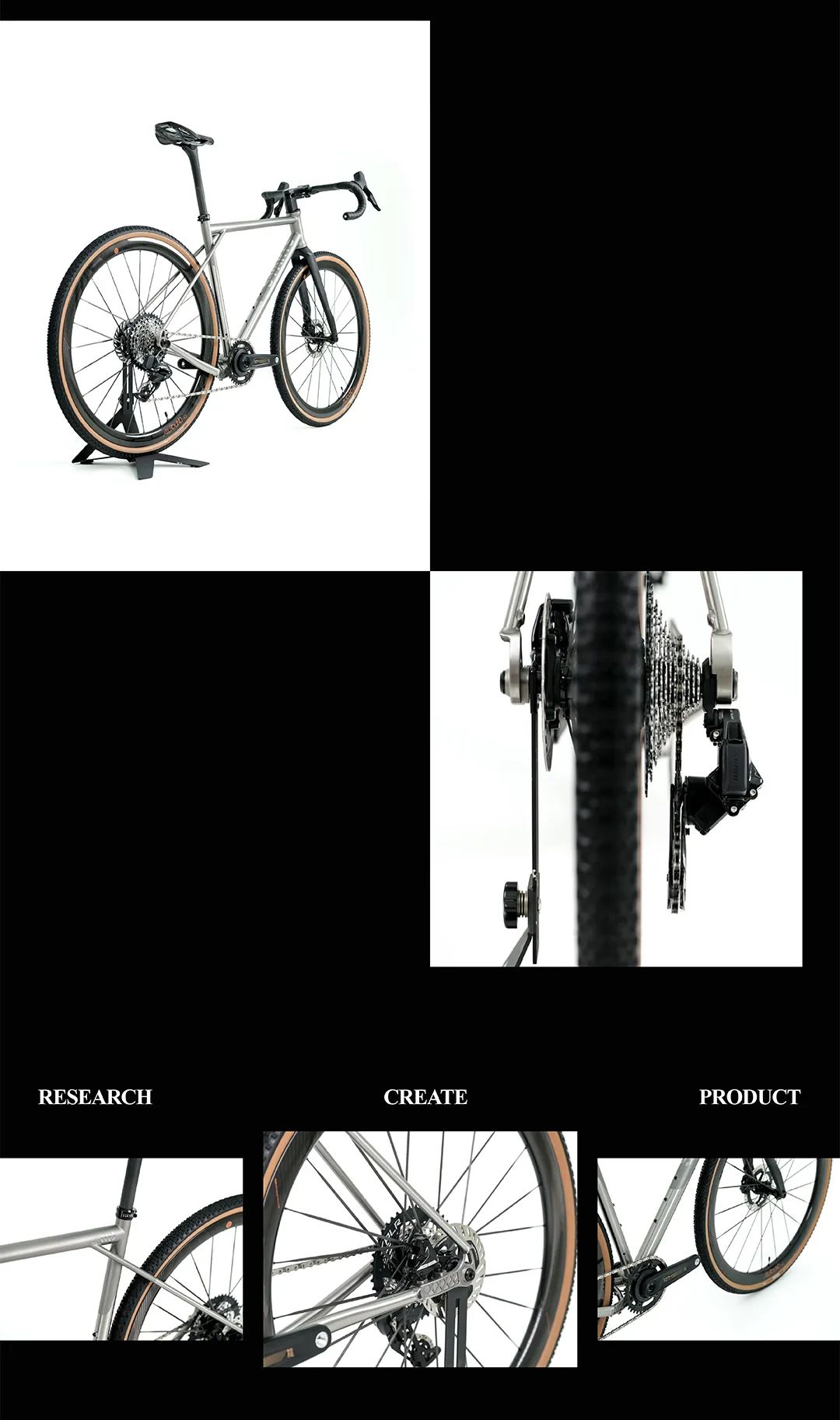

Internal cable routing / CNC rear dropout / UDH derailleur hanger / T47 bottom bracket

The frame features a 52mm integrated headset with uniform diameter, supporting ACR and DCR systems for fully internal cable routing with both integrated and non-integrated handlebars.

The fully CNC-machined flat mount brake caliper installation base ensures high strength and precise mounting holes for quick and accurate setup, delivering sharp and powerful braking performance.

The entire series is equipped with the UDH direct mount dropout system, compatible with nearly all rear derailleurs on the market.

The T47 threaded bottom bracket, standard across the series, is the optimal solution for metal frames, offering excellent stability, pedaling stiffness, and minimal noise risk. For 24mm spindle specifications, it supports a fully hidden brake hose routing solution within the bottom bracket shell.

Frame Assembly Guidelines

Head Tube: Use upper and lower 52mm integrated bearing headsets, ensuring compatibility with ACR or DCR system internal cable routing.

Fork: Optimal fork specifications for this frame are a length range of 389-400mm (excluding suspension forks), an offset range of 48-55mm, and a maximum tire clearance >42c.

Bottom Bracket and Crankset: The frame's bottom bracket shell width is 68mm and requires a T47 external bearing bottom bracket. The specific model depends on the crankset used; please consult your retailer or S-PARTS official customer service. The frame supports a maximum chainring size of 48T.

Shifting and Braking: The frame is compatible with DI2, AXS electronic shifting systems, and similar electronic shifting products (not compatible with any mechanical shifting systems). The frame only supports FLATMOUNT disc brake systems.

Seat Post: Only compatible with 27.2mm diameter round seat posts.

Wheelset: Only compatible with 700c wheel specifications and 12mm thru-axle road wheelsets.

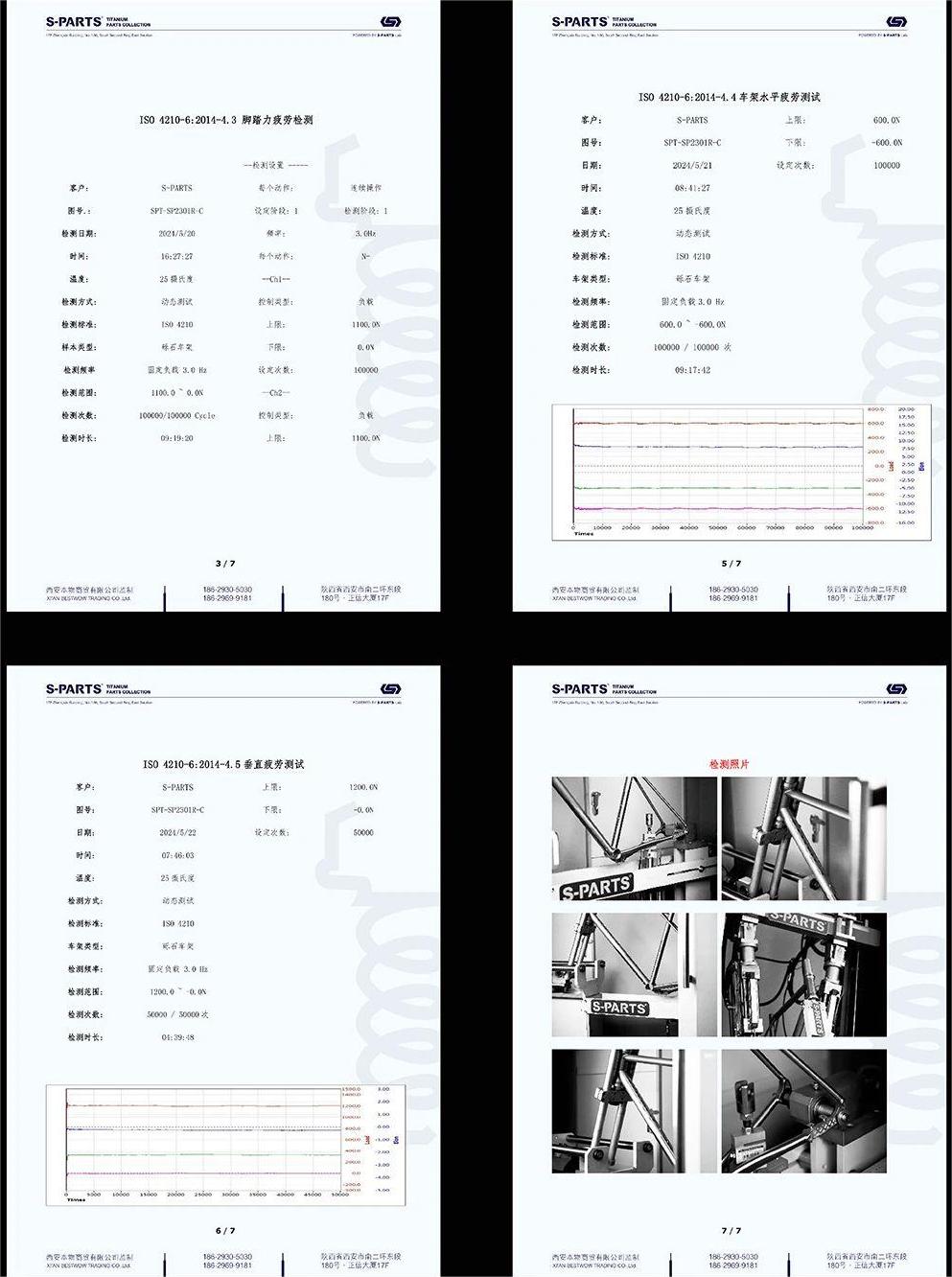

Gravel frame fatigue test report - Chinese

Compatibility Check: Due to the complexity of original equipment manufacturer (OEM) parts' models and batches, there may be instances where this product is incompatible.

Upon receiving this product, please compare it with the OEM specifications to ensure compatibility before installation.

Torque Specifications: Install this product strictly according to the torque values specified in the OEM parts manual.Installation Issues: If you encounter any discrepancies with the OEM specifications or face difficulties at the initial stage of installation, stop immediately and contact customer service for assistance with returns or exchanges.

No Forced Installation: Do not force installation under any circumstances.Liability: Any damages resulting from forced installation or unauthorized modifications of this product (or its components) will be the sole responsibility of the buyer.

All products are photographed to accurately represent the colors you will see upon receipt.

Due to differences in lighting, angles, or screen settings, slight color variations may occur.

The actual product should be considered the standard.For "colored" and "blue" products, the coloring process may result in uneven color distribution, making each product unique.

| S-PARTS Common Torque Reference Table for Bicycle Series | ||||||

| Ingredient | Component Name | Screw Name | Reference Torque | Anti-seize Usage | Medium-strength Threadlocker Usage | Special Requirements Remarks |

| Frame System | Handlebar Assembly | M4 Stem Fixing Screws | 4NM | Recommended | Consider with Caution | For special structure handlebar assemblies, please refer to the original manufacturer's recommended torque specifications. |

| M5 Stem Fixing Screws | 5NM | Recommended | Consider with Caution | |||

| M6 Stem Fixing Screws | 6-8NM | Recommended | Consider with Caution | |||

| M7 Handlebar Fixing Screws (Brompton) | 8-10NM | Recommended | Consider with Caution | |||

| M8 Stem Fixing Screws (BMX) | 8-10NM | Recommended | Consider with Caution | |||

| Headset | Headset Preload Screws (including M5/M6) | 4-6NM | Recommended | Not Recommended | ||

| Frame/Fork | M3 Fork Hose Clamp Screws | 1-2NM | Recommended | Not Recommended | For special structure seatpost clamps, please refer to the original manufacturer's recommended torque specifications. | |

| Water Bottle Cage Screws | 4NMM | Recommended | Not Recommended | |||

| M4 Derailleur Hanger Fixing Screws | 3-4NM | Recommended | Consider with Caution | |||

| M5 Derailleur Hanger Fixing Screws | 4-5NM | Recommended | Consider with Caution | |||

| M5 Front and Rear Rack Fixing Screws | 6-7NM | Recommended | Consider with Caution | |||

| M5 Seatpost Clamp Screw (Standard Clamp Design) | 6-7NM | Recommended | Not Recommended | |||

| Seatpost | M5 Saddle Rail Clamp Screws | 6-7NM | Recommended | Not Recommended | ||

| M6 Saddle Rail Clamp Screws | 7-9NM | Recommended | Not Recommended | |||

| M7 Saddle Rail Clamp Screws | 8-10NM | Recommended | Not Recommended | |||

| M6/M7 Single-Bolt Saddle Rail Clamp Screws | 10-12NM | Recommended | Not Recommended | |||

| M8 Single-Bolt Saddle Rail Clamp Screws (Brompton) | 12-14NM | Recommended | Not Recommended | |||

| Wheelset | M6 Quick-Release Wheelset Locking Screws | 6-8NM | Recommended | Not Recommended | ||

| M10 BMX Wheelset Locking Screws | Recommended | Not Recommended | ||||

| M14 BMX Wheelset Screws | Recommended | Not Recommended | ||||

| M9 Wheelset Locking Nuts | 12-14NM | Recommended | Not Recommended | |||

| M10 Wheelset Locking Nuts | 14-16NM | Recommended | Not Recommended | |||

| M12 Thru-Axle Bolt | 10-14NM | Recommended | Not Recommended | |||

| M14 Thru-Axle Bolt | 12-16NM | Recommended | Not Recommended | |||

| Brake System | Disc Rotor | Six-Bolt Disc Rotor Screws | 5-7NM | Consider with Caution | Recommended | Do not use anti-seize compounds or liquid thread lockers on screws related to the brake hydraulic system to avoid contaminating the hydraulic lines. |

| Center Lock Disc Rotor | 40NM | Recommended | Not Recommended | |||

| Brake Lever | M5 Brake Lever Fixing Screws | 5-7NM | Recommended | Not Recommended | ||

| M6 Brake Lever Fixing Screws | 6-8NM | Recommended | Not Recommended | |||

| Road Bike Shifter Fixing Nuts | 6-8NM | Recommended | Not Recommended | |||

| Brake Lever Bleed Port Screws | 2-3NM | Not Recommended | Recommended | |||

| Disc Brake Caliper | M6 Mountain Bike Caliper Fixing Screws | 9NM | Consider with Caution | Recommended | ||

| M5 Flat Mount Caliper Fixing Screws | 7NM | Consider with Caution | Not Recommended | |||

| M8 Hose Compression Fitting Screws | 6-7NM | Not Recommended | Not Recommended | |||

| M6 Caliper Body Screws | 12NM | Not Recommended | Not Recommended | |||

| M7 Caliper Body Screws | 14NM | Not Recommended | Not Recommended | |||

| M8 Caliper Body Screws | 14NM | Not Recommended | Not Recommended | |||

| M6 Caliper Banjo Screws | 12NM | Not Recommended | Not Recommended | |||

| Caliper Bleed Screws | 5-6NM | Not Recommended | Not Recommended | |||

| Brake Pad Pin | 3NM | Not Recommended | Not Recommended | |||

| C-Brake Caliper | Single Pivot Caliper Fixing Nut | 8NM | Not Recommended | Recommended | ||

| Dual Pivot Caliper Fixing Screws | 6-8NM | Consider with Caution | Consider with Caution | |||

| Brake Pad Fixing Screw Set | 7NM | Consider with Caution | Consider with Caution | |||

| Brake Pad Stop Screws | 3NM | Not Recommended | Not Recommended | |||

| Caliper Release Lever Screws | 3NM | Not Recommended | Not Recommended | |||

| Cable Anchor Screws | 5-7NM | Recommended | Not Recommended | |||

| Drivetrain System | Shifter | Shifter Clamp Bolt | 4-6NM | Recommended | Not Recommended | Do not use anti-seize compounds or liquid thread lockers on screws related to the brake hydraulic system to avoid contaminating the hydraulic lines. |

| Shifter Integration Bolt | 4-6NM | Recommended | Not Recommended | |||

| Shifter Top Cap Bolt (Shimano) | 4NM | Recommended | Not Recommended | |||

| Front Derailleur | Direct Mount Front Derailleur Fixing Bolt | 6-7NM | Recommended | Not Recommended | ||

| Front Derailleur Clamp Bolt | 5-7NM | Recommended | Not Recommended | |||

| Front Derailleur Cable Adjusting Bolt | 5-7NM | Recommended | Not Recommended | |||

| Rear Derailleur | Rear Derailleur Pivot | 10-12NM | Recommended | Not Recommended | ||

| UDH System Rear Derailleur Pivot | 25NM | Recommended | Not Recommended | |||

| M4 Pulley Bolt | 3NM | Consider with Caution | Consider with Caution | |||

| M5 Pulley Bolt | 4NM | Consider with Caution | Consider with Caution | |||

| M3 Rear Derailleur Lock Cover Bolt (Shimano) | 1.5NM | Not Recommended | Not Recommended | |||

| Rear Derailleur Cable Adjusting Bolt | 5-7NM | Recommended | Not Recommended | |||

| Crankset | Chainring Double-Sided Bolt | 6-8NM | Consider with Caution | Consider with Caution | ||

| Single Chainring Bolt | 8NM | Consider with Caution | Consider with Caution | |||

| M5 Crank Arm Bolt (SRAM 3-bolt) | 7NM | Consider with Caution | Consider with Caution | |||

| M4 Crank Arm Bolt (SRAM 8-bolt) | 4-5NM | Consider with Caution | Consider with Caution | |||

| M6 Crank Arm Fixing Bolt (Shimano) | 12-14NM | Consider with Caution | Consider with Caution | |||

| Crank Arm Cap (Shimano) | 2-4NM | Not Recommended | Not Recommended | |||

| Crank Arm Fixing Bolt (DUB) | 54NM | Recommended | Not Recommended | |||

| Crank Arm Fixing Bolt (Rotor) | 30-35NM | Recommended | Not Recommended | |||

| Crank Arm Fixing Bolt (EE) | 52NM | Recommended | Not Recommended | |||

| M8 Square Taper Crank Bolt | 30NM | Recommended | Not Recommended | |||

| Pedals | Pedal Axle | 25NM | Recommended | Not Recommended | ||

| Road Cleat Fixing Bolt (3-bolt) | 6-8NM | Not Recommended | Recommended | |||

| MTB Cleat Fixing Bolt (2-bolt) | 8NM | Not Recommended | Recommended | |||